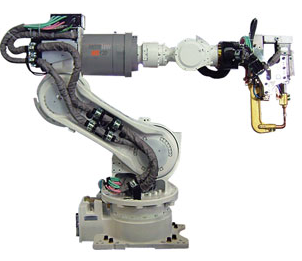

Quick and agile, the six-axis MS120 “Master

Spot” welding robot features a 120 kg (264.6 lb) payload and is more than 43 percent

faster than a traditional heavy-payload robot, resulting in shorter takt times and higher

throughput. Specifically designed to optimize automotive applications using DC spot

guns with compact servo actuators, the slim-profile MS120 robot can be placed in

close proximity to workpieces and other robots to create flexible, high-density layouts. These configurations

can eliminate multiple stations, resulting in shorter production lines and smaller spot welding workcells.

Because it uses a lighter gun, the MS120 robot uses 33 percent less power even at its faster speeds. When

combined with the improved efficiency of the smaller DC guns, the MS120 robot offers a 50 percent power

savings.

With a streamlined body less than 500 mm (19.7”) wide, including the integrated spot harness, the compact

MS120 robot has a 1,623 mm (63.9”) reach with a repeatability of ±0.2 mm (0.008”). The short-reach MS120

robot is designed to be mounted close to car bodies or other parts, and its low profile allows larger robots to

reach over it to work. Spot utilities (power, water, air, motor and signal lines) are integrated into the profile of

the robot arm preventing interference and reducing programming time. Integrated harnesses also last more

than six times longer than traditional harnesses, reducing maintenance and improving uptime.

Fast processing of the DX100 robot and system-level controller speeds commands for the MS120 robot, while

Motoman Robotics’ patented multiple robot control (up to 8 robots/72 axes) provides superior collision

avoidance features and facilitates programming. Advanced control functions optimize robot acceleration

characteristics, reducing cycle time. Featuring a robust PC hardware architecture, the DX100 controller uses

a Windows® CE programming pendant with color touch screen. |

| عن هذه الشركة: |

Motoman Robotics is a division of Yaskawa America, Inc., the world

leader in robotics, and operates in North and South America.

Combined with our sister and partner companies, we can support

robotic solutions throughout the world. Our proven track record of

delivering industry leading quality, innovation and customer

satisfaction can help you exceed your robotic automation goals.

|

| معلومات عن الشركة: |

| اسم الشركة: |

Yaskawa America, Inc. |

| عنوان: |

2121 Norman Drive |

| مدينة: |

South Waukegan |

| دولة: |

IL |

| ZIP: |

60085 |

| بلد: |

U.S.A. |

| رقم الهاتف: |

+1-847-887-7000 |

| الفاكس: |

+1-847-887-7310 |

|

|

|