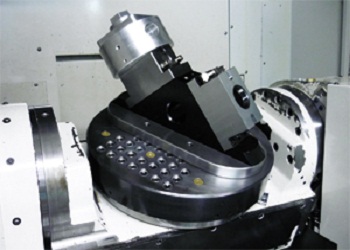

Hoffman Estates, IL – BIG Kaiser Precision Tooling Inc. has strengthened and expanded its Unilock line of 5-axis workholding product offerings. These multi-axis workholding products are designed to provide flexibility and functionality for 5-axis machining and 5-sided machining via multiple part transfers. These solutions are also for machines with retrofit 4th/5th axis tables, and can help maximize benefits so your machine's design through efficient workholding.

These multi-axis workholding solutions locate and stabilize the workpieces without obstructing access to the top and sides of the part. They also allow a clamped workpiece to be flipped into new orientations for subsequent machining operations without unclamping it from the workholding.

"BIG Kaiser's unique approach to 5-axis workholding seamlessly fits into existing workholding solutions while providing the increased flexibility of Unilock zero-point solutions," says Gerard Vacio, product manager, workholding systems. "Our clients match workholding to the workpiece and maximize the capabilities of their 5-axis machine tools. We can also provide specific solutions for your dedicated production requirements. We interface virtually any workholding product that fits in the machine."

The 5-Axis Duo Bridge, with Dual 45° 105/65 Base Plates, are integratable solutions that can be mounted directly on the top of a 5-axis table or loaded through a pair of zero-point chucks. Unilock's 5-Axis Riser Chucks, Extensions and Reductions, with a working diameter of 80mm, are available on base plates, or as stacking modules in heights of 75mm and 100mm. And the infinitely adjustable First Grips and Dovetail Grips are only limited by the length of the thread that pulls the jaws together. |